Massimiliano Russello, Team Leader in Composite Welding Technologies at AIMEN and a member of the HERWINGT project team, will present the abstract titled "Sequential Resistance Welding of a Thermoplastic Composite Leading Edge Demonstrator: From Laboratory Testing to Full-Scale Welding" at the 24th International Conference on Composite Materials (ICCM24). The presentation will highlight the innovative use of sequential resistance welding for thermoplastic composites, detailing the transition from laboratory-scale testing to full-scale industrial application, and emphasizing the HERWINGT project's contributions to sustainable and efficient aeronautic manufacturing technologies.

ABSTRACT

SEQUENTIAL RESISTANCE WELDING OF A THERMOPLASTIC COMPOSITE LEADING EDGE DEMONSTRATOR: FROM LABORATORY TESTING TO FULL-SCALE WELDING

M. Russello, E. Chemello, R. González Gil, A. Martínez Domínguez, E. Rodríguez Senín

Thermoplastic composites, which have the unique potential to be recycled, reprocessed, and welded, are the focus of a worldwide aeronautic challenge to progress toward greener and more sustainable global transportation. Adopting more flexible and adaptive production technologies that allow for quicker manufacturing cycles, higher environmental friendliness, and increased productivity is a further challenge. Aiming to commit to the drastic projected increase in aircraft production rates together with the need of weight and drag reduction, the HERWINGT project, focused on the next-generation wing technology, has promoted the development and investigation of highly integrated and robotized manufacturing technologies that needed to be scaled up from a laboratory to an industrial environment.

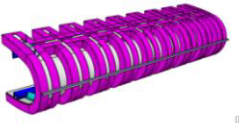

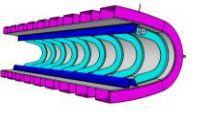

Sequential Resistance Welding, being one of these, is a promising technique for joining thermoplastic composite structures capable of meeting the required industrial needs as it is easily integrable, fast, and reliable. For this reason, this study looked at the use of an innovative sequential resistance solution to weld a thermoplastic leading edge to its coupled internal ribs.

This research aimed to validate and further investigate the temperature effect when welding thick and curved composite parts and understand how welding parameters such as current, time, pressure, active cooling, welding direction, as well as, material parameters, affect the weld quality. A great focus was given not only to the fabrication of an innovative carbon-based heating element capable of generate customized heating patterns but also, to the control system that enable the capability to real-time reaction and re-adjustment to the live-changing process. Various strategies that aims to industrialize the Welding process were developed and a scale-up analysis performed. Power, current, voltage, pressure and temperature sensors were used to investigate the evolution of the process. Welding investigation, including process maturation, parameter optimization, and scale-up analysis were performed at the laboratory scale using PEEK/CF composites while the welds were characterized by visual inspection, microscopy analysis, and mechanical testing (SLSS tests).